Abstract

The objective of this paper is to model a hybrid power system for buildings, which is technically feasible and economically optimal. With a view to promote renewable energy sources, photovoltaics and wind turbines are integrated with the grid connected building. The system is modeled and the optimal system configuration is estimated with the help of hybrid optimization model for electric renewables (HOMER). The logic is illustrated with a case study based on the practical data of a building located in southern India. This building is associated with 3.4 MWh/day priority load (peak load as 422 kW), as well as 3.3 MWh/day deferrable load (peak load as 500 kW). Sensitivity analysis is performed to deal with uncertainties such as the increase in electricity consumption and grid tariff, environmental changes, etc. From the simulation result, it is observed that the designed system is cost effective and environment friendly, which leads to 6.18 % annual cost savings and reduces CO2 emissions by 38.3 %. Sensitivity results indicate that the system is optimal and adaptable in a certain range of unanticipated variances with respect to best estimated value. Finally, an energy management strategy is developed for the optimal system to ensure reliable power during contingency and disturbances. The green and hybrid power system designed can be adaptable to any critical and large consumers of urban buildings.

Similar content being viewed by others

1 Introduction

India, a dwelling place for 1.21 billion people, which is over 17 % of the world’s population, has a seemingly unquenchable thirst for energy. One blaring result of its meteoric growth is the widening gap between the energy demand and the supply; therefore, the government is paying increased focus to bridge the gap by capacity addition. In chorus, attention is being paid to that the growth should be in a sustainable manner while addressing the climatic change concerns. In 2008, with the announcement of the National Action Plan on Climate Change (NAPCC), there is a marked shift in policy to diversify the energy mix to the lower carbon intensity [1]. Besides, low-carbon generation systems bring competition in electricity markets and are in turn improves the country’s sustenance and economy [2]. Nowadays, the country is promoting renewable energy to augment the total power supply and to meet the rural needs either by augmenting grid supply or by off-grid supply.

The statistics show that approximately 38 % of the total electric energy production is being consumed by the industrial sector, which is playing a crucial role in the economic growth of the country. With India emerging as an IT/BPO hub, erratic power supply hampers the business process, which ultimately reflects on the country’s economy. Besides, cross subsidies, higher tariff, power outages, load shedding and inconsistent quality of power supplied by utilities are other factors that adversely affect such industries. With the demand far outstripping the electricity generation in the country, many industries are now looking at alternatives based on the guidelines and roadmaps given by various forums and government bodies for clean energy generation [3, 4]. The solution as envisioned by many organizations is to set up captive power plants for electricity generation or diesel generator set as a back-up, which is again not a clean energy.

In this framework, the hybrid and green power system uses renewable energy resources that are available at the site of use and are used to produce electricity in and around the premises of the building in an economic way. An energy management strategy is developed, which ensures uninterruptable power supply to all the priority loads connected to the building. Optimization result shows that the system is cost effective and reliable with less carbon emission. Sensitivity analysis shows that the system performance is nearly optimal in all scenarios.

1.1 Literature review

Below literature indicates some of the related works carried out in the design of low-carbon electricity systems. Various studies were done on microgrid formation for a particular combination of distributed units in a location. This paper deals with the formation of microgrid with various combinations of distributed resources to achieve a sustainable design for the low-carbon power system. Further, it compares all the combinations in terms of cost and carbon emissions to select best sized microgrid for a specific case study. Finally, optimum energy usage is achieved by the design of energy management strategy.

Reference [5] identified and suggested some insights for the people live in Germany and USA to choose and develop low-carbon electrical power generation systems. It also presented the advantages of low-carbon initiatives and crisis with the nuclear based generation systems briefly. Reference [6] presented the design of low-carbon optimum evaluation model by using multi-objective function to improve the efficiency of carbon footprint calculations. This considers dealer manufacturing capacity, green-house gas values, product components transport modes, design phase costs, as well as the product decisions made by enterprises. Reference [7] presented the scenarios and consideration of combined nuclear and renewable based energy systems design in Japan in 2030 to adhere the country’s policies of CO2 emission reduction. The safe and clean electricity was analyzed for “smart control” on both demand and supply sides. Reference [8] presented whole-systems method to appreciate the role of grid-scale electricity storage by concurrently optimizing investment into network and storage capacity, new generation. This minimizes system operation cost by considering system’s reserve and security constraints. Reference [9] presented an integrated methodology that considered demand responses and renewable generation as inputs for the distribution system planning to make the system as a low-carbon sustainable system. This method optimized the allocation of renewable/non-renewable units and smart metering units simultaneously to minimize total carbon emissions cost. Similar integrated model for low-carbon power generation in China was presented in [10]. Reference [11] presented a comprehensive model to study low-carbon power system dispatches. The operating mechanisms and characteristics were analyzed by considering feasible power output limits, rates, and the carbon emissions. Reference [12] presented a generation output model to evaluate the power dispatch problems under low-carbon and economy systems development. In [13–16], similar analysis was carried out for the design of low-carbon electricity systems and study on their impacts on the energy crunches for different cases.

Reference [17] presented the design of hierarchical control for microgrids. Energy management system was designed to achieve a reasonable balance between generation and battery usage. However, the system was developed only for island mode but not for grid tied mode. Reference [18] presented the dynamic behavior of a mixed system consisting of a wind farm and a diesel group supplying a load, under different disturbances. Reference [19] presented two droop control strategy for distributed generation in interconnected grids. Reference [20] presented a simulation model to investigate specific hybrid architecture, which is based on the use of DC bus, DC/AC and DC/DC converters for power sources. This increases number of converters usage and leads to high cost and poor quality. Reference [21] had done an optimal cost analysis of hybrid renewable system using hybrid optimization model for electric renewables (HOMER). The real time cost analysis and system optimization was done based on the load profile, solar radiation and wind speed. Reference [22] and [23] described the integration of wind power into traditional diesel-only power system, which reduced greenhouse gases and thereby global warming. The wind-diesel power plant was designed, and the operational and economic analysis were compared with traditional diesel system using HOMER. In [24], the distributed energy resource system was designed and simulated. The cost analysis was done by calculating net present value. Reference [25] presented microgrid with micro-controller based energy management unit. Hydro generators, PV panels, and diesel generators were integrated to study the generation patterns under various ecological conditions. Reference [26] presented a voltage and frequency control strategy for active island microgrids design. There are few literatures available on the study of economic and technical feasibility of microgrids and hybrid systems in [27–33]. However, most of these were designed for standalone systems of remote areas, where it is either difficult or impossible to extend the grid service. And these studies considered the loads in a nonspecific manner. This paper focuses on the grid-connected HPS developed for a practical case study.

2 Hybrid power based microgrid description

Microgrids are formed by the hybrid interconnection of various units such as AC and DC energy sources, storage, AC and DC loads, AC/DC, DC/DC, or DC/AC converters. The selection of any architecture for a location depends on the geographical, economical, and technical factors at that location. The architectural segregations are as follows.

3 Case study description

In this case study, the considered building is an organization located at Hyderabad, India. The area enclosed by the building is about 125000 sq ft. The existing architecture of the building is that it is connected to the utility grid that serves the entire load connected. A diesel generator set was also installed to meet certain portion of the load at the time of grid outage. The new proposed architecture of the system is that the electric energy produced from the PV and WT augments the grid supply to meet the demand. A converter is connected to convert the DC power produced by the PV array to AC, as the entire load served is the AC type. A 396 V battery bank is also connected to the DC bus, which can store energy and be used as a backup energy source. The system is modeled, and the best configuration of hybrid system is estimated by using HOMER [34, 35]. The profiles of load demands and energy resources are given as follows.

3.1 Load profile

The analysis does not perceive the entire load connected to the building. Moreover, it categorizes the load in the most smart and reasonable way. The type of load that is connected to this building and other such buildings are heating, ventilation, and air conditioning (HVAC) load, uninterrupted power supply (UPS) load, air handling unit (AHU) load, lighting load and other utility loads. These loads are further classified as shown in Table 1.

3.1.1 Priority load

These loads are electrical demand that the power system must serve at a specific time. In any business or industry, computers are the integral part, thus all the UPS load is considered as a priority load. Other loads associated with this category are lighting load and some utility loads like elevators. As these loads varies according to time of the day and also do not attain the same value for weekdays and weekends, a separate survey for this category of loads is needed. The variation of this load is recorded for a year (separately for weekday and weekend), to make the data more realistic. An average 5 % day-to-day and hour-to -hour randomness are added to the practical data such that load profile of each day is unique. Figs. 5 and 6 illustrates a typical profile of the priority load.

3.1.2 Deferrable load

Deferrable loads can be classified as an electrical demand that can be met anytime within a definite time interval. Typical example of this load type is the chiller load, AHU load, water pump load, battery charging station, etc. Certain amount of energy is stored in such type of devices and is generally switched on intermediately. For example, after the chiller unit and the pump associated with it are charged to its full capacity, it can serve the building for certain period without demanding electrical input. This type of load is often advantageous as one can track the level of energy that is stored in this load type, and can put excess renewable energy into this as long as energy level is above zero. Once the energy level drops to zero, these loads can be treated as a priority load and can be served immediately. The typical monthly variation of such load type is shown in Fig. 7.

3.2 Solar and wind resources

The considered building is located at a latitude of 17.37 (North), longitude of 78.47 (East), and an altitude of 536 m. It experiences a combination of tropical wet and dry climate [36]. The place is blessed with around 5.34 kWh/m2 yearly average daily solar radiation and more than 6 kWh/m2 maximum radiation in March, April and May. The radiation data can be obtained from the database of NASA [37]. The monthly average of solar radiation and clearness index is shown in Fig. 8. Recorded data shows that the monthly wind speed in a year is 4.141 m/s. Fig. 9 illustrates the wind speed variation throughout the year [38]. From the solar and wind resource data, it is clear that June, July, and August are experiencing less solar radiation, but the wind speed compensates this effect and makes the total natural resource available throughout the year.

4 Hybrid power system modeling and simulation

4.1 Introduction to HOMER and system simulation

HOMER is a micro-power optimization tool, which is developed by the U.S. National Renewable Energy Laboratory (NREL). It models the physical behavior of a power system and calculates its lifecycle cost or the total net present cost (TNPC), which includes installation and operating cost of the system over its life span. The modeler provides the solar and wind resources data, load profile of the building to be served by the HPS, components to be considered and their cost as input to the HOMER. The HOMER then performs an hourly energy balance calculation for each configuration for a year. After simulating all the possible configurations, the infeasible configurations are discarded and the feasible solutions are ranked according to the TNPC. It also allows the user to perform the sensitivity analysis on various inputs to access the effects of uncertainty on which the system has no control. Fig. 10 illustrates the relationship among simulation, optimization and sensitivity analysis. The optimization oval encloses the simulation oval to represent the fact that a single optimization consists of multiple simulations. Similarly, the sensitivity analysis oval encompasses optimization oval, representing that a single sensitivity analysis consists of multiple optimizations.

4.1.1 Simulation

Microgrid architectures with different combinations of distributed resources are developed for the performance analysis in each hour of the year to determine its technical feasibility and life-cycle cost. Energy balance calculations are performed based on the system architecture consisting of different combinations of the components. This paper chooses PV, WT, diesel generators, battery, and converter as the elements of HPS and the best feasible configuration is determined that can adequately serve the load.

4.1.2 Optimization process

Power system should be appropriately designed in terms of economy, reliability, and ecological measures subjected to various physical and operational constraints of the location. The optimal system configuration can be decided with the mixture of components that the system should comprise the quantity of each component and the dispatch strategy the system should use. The overall objective is to identify a configuration which has low TNPC. Therefore, different system configurations and technical constraints are simulated and formed various combinations of system components. Finally, a list of configurations are sorted out and compared. Best feasible combinations are extracted and the least feasible ones are omitted. The overall optimization process is shown in Fig. 11. The objective function of the optimization problem is given by (1).

where TNPC can be calculated by (2).

Overall system annualized cost (C i ) in general form is calculated as the sum of costs of all components and is given by (3). This cost consists annualized costs of the components procurement, replacement, and operations including fuel maintenance. Hence, the total TNPC value is calculated as the sum of TNPC of each component.

where C PV , C WT , C DG , C BAT , C CONV are the costs of PV, WT, diesel generator, battery, and converter; i the index of PV, WT, battery, converter, and diesel generator; N i the total number of system components; CptlC i the capital cost of a component; RplC i the replacement cost of a component; M i the single payment present worth of a component; OMC i the operation and maintenance cost of a component; CRF the capital recovery factor; R the project lifetime; and ir the annual interest rate for the project life time.

4.1.3 Sensitivity analysis

As the TNPC varies based on sensitivity variables chosen, in this analysis, multiple optimizations are performed to measure the effects of the uncertainties such as wind speed, solar radiations, grid tariffs, and fuel prices on the system performance. Hence, the HPS configuration has to be chosen to tolerate all these situations.

4.2 Microgrid system modeling

The microgrid system is formed as an interconnection of various distributed units such as PV, WT, utility grid, diesel generator, converter, and battery that are modeled as shown below. It is important to know the technical and economic detail of these units precisely to get an accurate simulation result. Besides, decisions on system control parameters, constraints, and economic inputs have an equal effect on the simulation results.

4.2.1 PV panel modeling

The model of the PV array is developed that it produces DC electricity in direct proportion to the global solar radiation. It is independent of temperature and voltage to which it is exposed. Output power is given by (5).

where f PV is PV derating factor; Y PV the rated capacity of the PV array; I T the global solar radiation incident on the surface of the PV array; and I S is 1 kW/m2 which is the standard amount of radiation used to rate the PV capacity.

The range of the PV array rating is permitted to vary between 125 kW and 275 kW to choose the optimal size. The capital cost of the PV panel is 3500 $/kW and after a reasonable percentage of discount on bulk amount, the replacement cost is considered as 3400 $/kW. The subsidy provided for using solar energy was also discounted in the given capital cost. Operation and maintenance cost for the PV array is considered as 0 $. The lifetime of the selected PV array is 25 years with a derating factor of 85 %. Two-axis tracking system is established for the PV panel.

4.2.2 WT power unit modeling

Wind turbine converts kinetic energy of the wind into AC electricity according to a particular power curve. Each hour, power output of the wind turbine is calculated in a four-step process. Firstly, it determines the average wind speed for the hour at the anemometer height by referring to the wind resource data. Secondly, it calculates the corresponding wind speed at the turbine’s hub height using either the logarithmic law or the power law. Thirdly, it refers to the turbine’s power curve to calculate its power output at that wind speed assuming standard air density. Fourthly, it multiplies output power by air density ratio.

The rating of each wind turbine considered is 50 kW, AC. Range of 2 to 5 numbers of such turbines is taken as decision variable. The cost of each wind turbine is 181035 $. The subsidy provided to set up wind firm is deducted in the given capital cost. Operation and maintenance cost of the wind turbine is 4320 $/year/turbine and the total operation and maintenance cost is reduced as the number of turbines increases. The lifetime of the turbine is 25 years and the height of the turbine hub is 40 m.

4.2.3 Battery system modeling

Batteries are used to store excess power in the HPS, and to operate when the system has deficit power. Its life depends on how many times the battery is charge/ discharge per day. Battery bank is formed for 396 V DC bus. The rating of each battery is 12 V, 200 Ah, 2.4 kWh. A string of 33 such batteries are connected in series to deliver the power at a desired voltage level. The cost of each battery is 475 $ and the replacement cost is 430 $. The battery lifetime is 10 years. Value of 0, 1 and 2 strings was entered as decision variable.

4.2.4 Diesel generator modeling

A diesel generator consumes fuel to produce electricity, and possibly heat as a by-product. The fuel curve is assumed as a straight line with a y-intercept and uses (6) for the generator’s fuel consumption. Diesel generators are added to the microgrid system to cover the peak load. Moreover, they can supply the electric demand when the RES system is producing insufficient power.

where F 0 the fuel curve intercept coefficient; F 1 the fuel curve slope; Y gen the rated capacity of the generator; and P gen the electrical output of the generator.

Three diesel generator sets are installed in the existing system (one with a capacity of 380 kW and the second, third sets with a capacity of 1055 kW each). The capital cost is not considered as these are already installed but operation and maintenance cost of 0.002 $/hour was taken into account. Cost of the diesel is 0.9 $/liter. The lifetime of diesel generator set is 15000 operating hour and the minimum load factor is 30 %. In the decision variable, ‘0’ value was also included to obtain the most optimal unit.

4.2.5 Converter modeling

The rating of the converter (working as both rectifier and inverter) is chosen according to the total PV panel output, as the total PV panel output is converted in to AC by the converter. Hence, the size considered for converter is 125 kW to 275 kW, with a cost of 110 $/kW. The replacement cost is 100 $/kW. The lifetime of converter is 20 years with an efficiency of 95 % in both the directions.

4.2.6 Utility grid

In this model, the building is connected to the utility grid, and the building produces maximum demand of 600 kW on the utility grid. The tariff of the electricity charged by the utility is 0.065 $/kWh of energy consumption and demand rate of 5 $/kW/month [39]. The interconnection charge paid to the utility is 8000 $.

4.2.7 System control and constraints

The dispatch strategy selected for this system is “load following” type. The simulation time step is kept at one hour [40] and is performed with the following constraints.

-

1)

The operating reserve is set at 7 % of the total energy demand and 20 % of each solar and wind power output.

-

2)

The minimum renewable fraction (RF) is set at 35 %, i.e. at any moment the minimum energy from RES is 35 % of the total energy consumed at that moment.

-

3)

Maximum annual capacity shortage is set at 0 %.

4.2.8 System economics

The lifetime of the project is considered for 25 years at an annual interest rate of 6 % throughout. Also, it is supposed that there is no capacity shortage penalty. The overall microgrid system model is shown in Fig. 12.

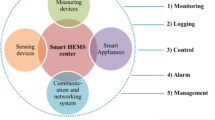

5 Energy management strategy

While simulating the proposed system, it was assumed that the grid is supplying rated energy, and RES produces nominal power throughout the project lifecycle, which is not obvious. Again, while perceiving the grid in Indian context, the grid outage and load shedding occur in an unpredictable manner. In this case, the microgrid designer faces a major challenge as to how reliability can manage and coordinate with the energy system. In simple term, managing the energy system means, how smartly use the available energy from all the sources to meet the load reliably [41, 42]. A simplified energy management method is presented here by considering four operation states.

5.1 Normal operating condition

In this state, it is assumed that the grid is supplying required energy and the RES are producing energy as per the nominal rating. In this case, just like the “load following” strategy, the priority loads are served by the grid and the deferrable loads are served by the RES. Excess renewable energy is used to charge the battery.

5.2 Grid outage

This state occurs during load shedding or an occurrence of fault in the transmission or distribution lines so that the utility is unable to serve the load. Simulation result shows that the renewable sources in the system produce 38 % of total energy in a year with minimum renewable fraction of 35.6 %. Thus in this state, the energy produced from the renewable source is fed to the most important priority load (i.e. UPS load which is 32 % of total energy consumption at any time). The excess renewable energy can be fed to other priority loads in the order of lighting, elevator, etc.

5.3 Unavailability of renewable energy sources

Sometimes due to constant poor solar radiation and wind speed less than the cut-in speed of the turbine, the renewable energy sources do not respond. During such period, the grid energy can be used to serve the entire priority load and a fraction of important deferrable load.

5.4 Total blackout

In this state, it is assumed that, the unavailability of the RES due to climatic condition and grid outage occurs at the same time. This can be the worst case and may rarely occur. In such scenario, the system is also capable to meet the priority load. Fig. 13 shows the frequency of state of charge (SOC) of the battery. It is clear that around 57 % time in a year, the battery is in 100 % SOC. Besides this, the building installed the diesel generator set which can be synchronized on demand. Battery and diesel generator set can serve the priority load and can also be extended up to certain deferrable load.

6 Simulation results

The microgrid architecture is simulated in various aspects based on the variations in load profile, component cost and size, system constraints, control strategy, and system economics. The cumulative simulation results can be segregated as follows.

-

1)

Energy management results

-

2)

Optimization results

-

3)

Sensitivity analysis results

6.1 Energy management results

Energy management results indicate the energy availability and transactions between microgrid and utility grid as shown in Figs. 14, 15, 16, 17, 18, 19 and 20 respectively.

6.2 Optimization results

HOMER considers all the possible combinations that are available in the search space to form the microgrid and checks the feasibility of each system configuration by imposing all the user specified constraints. TNPC for all the feasible system is calculated and sorted accordingly. Table 2 ranks the list of categorized optimization results for the microgrid. From the optimization result, it is clear that the most economic system configuration consists of the 180 kW PV array, three WTs, one battery string, a 160 kW converter and a grid connection having the demand of 600 kW. The TNPC for this configuration is 2878236 $.

The breakdown of TNPC is as follows: 968589 $ capital cost; 27248 $ replacement cost; 1885545 $ operation and maintenance cost; 0 $ fuel cost; and 3146 $ salvage value. This system has levelized 0.092 $/kWh cost of energy and produced 35.6 % minimum renewable energy. The considered ‘zero’ capital cost for diesel generator set does not impact on TNPC, as the optimal configuration does not include diesel generator set. Fig. 21 presents the electricity produced from different sources in a year.

The system has unmet load of only 1167 kWh/year which is 0.05 % of the total load. The total annualized cost is calculated [43]. In comparison, the grid-only connected system, that has a total annualized cost of 240000 $ and microgrid system, that has total annualized cost of 225155 $ produces savings of 14845 $ per year. Table 3 shows a comparison between the existing grid-only connected system and the proposed microgrid system.

6.3 Sensitivity analysis results

As there are several sensitivity variables on which the user has no control, several sensitivity analyses were also performed on the optimal system configuration to guarantee that the proposed system configuration is optimal, robust and adaptable in unanticipated variances with respect to best estimated value. Some examples of such variable are environment changes like solar radiation and wind speed variation, variation in the total electricity consumed, grid tariff and demand rate variation, etc.

6.3.1 Effect of solar radiation and wind speed variations

The solar radiation and wind speed is allowed to vary from 90 % to 110 % of its measured value. For all the values in this range, simulation is done and the results indicate that the same system configuration is optimal for this variation. The sensitivity result and TNPC variations are shown in Figs. 22 and 23 respectively.

6.3.2 Effect of electricity consumption variations

As the connected load or total electric consumption in the building will not remain constant throughout the lifetime of the project, it is also considered as one of the sensitivity variable. Both priority and deferrable loads are varied from 100 % to 105 % of the present value. For this variation, the sensitivity result shows that the same system type is optimal. It is also observed that priority load variation is more influential to TNPC than deferred load. Fig. 24 illustrates the variation of TNPC with load.

6.3.3 Effect of utility grid tariff variations

As grid tariff keeps increasing to influence customer behavior, it is taken as another sensitivity variable for the evaluation. In this case, the grid tariff is allowed to vary up to 0.085 $/kWh and demand rate is also varied from 5 to 6 $/kW/month. The sensitivity result for grid tariff and demand rate variation shows that beyond grid tariff of 0.07 $/kWh, battery bank is discarded instead, the capacity of the PV is increased. Fig. 25 shows that the TNPC is more sensitive to grid power price to that of demand rate.

6.3.4 Effect of variation of minimum renewable fraction and shortage capacity fraction

It is considered that the proposed system must able to produce 35 % minimum renewable energy of the total electric energy consumed, which is a user specified constraints and depends on system design. This value can be varied as per the user choice and causes remarkable impact on the TNPC. Similarly, one more constraint imposed during the simulation process is maximum annual capacity shortage. This parameter is set at ‘0’ as the building cannot compromise with reliability or interruption in energy supply. With this assumption, the system configuration is estimated that the system is able to supply peak load, which even occurs for a short interval.

However, practically if the peak load for a very short period can be avoided, then the system configuration and NPC may be other than as above. Thus, a sensitivity analysis for variation of minimum renewable fraction from 35 % to 40 %, and maximum annual capacity shortage vary from 0 % to 1 % is performed. It is observed from the simulation result that, for this variation, beyond minimum capacity shortage fraction of 0.37 %, battery is discarded from the system. TNPC variation is shown in Fig. 26.

7 Conclusion

Hence, the design aspects of renewable energy based microgrid are discussed in this paper. The study is conducted for an urban building having 3.4 MWh/day priority load along with a 3.3 MWh/day deferrable load. The cumulative merits of this system are as follows.

-

1)

The most economic system configuration is achieved for the combination of 600 kW utility grid contribution, 180 kW PV contribution, and 3 units WT contribution (50 kW for each, 150 kW in total), 33 batteries (1 string) and a 160 kW converter.

-

2)

The levelized cost of energy of such system is achieved as 0.092 $/kWh which is less than the grid-only connected system.

-

3)

Besides, the system is environment friendly and beneficial for sustainable development which leads to 6.18 % annual cost savings and reduces CO2 emissions by 38.3 %.

-

4)

From sensitivity results, it was observed that the system work satisfactorily in a range of varying scenarios such as solar radiation, wind speed and increase in energy consumption.

-

5)

The energy management strategy developed ensures uninterruptable and reliable supply for the priority load for smooth running of the business.

References

National Action Plan on Climate Change, Ministry of Environment, Forest, and Climate Change, Government of India. http://envfor.nic.in/ccd-napcc

Thomas S (2014) Are low-carbon generation and competitive electricity markets compatible? Evidence from the UK electricity market reforms. In: Brunnengräber A, Di Nucci MR (eds) Im Hürdenlauf zur Energiewende. Springer, Berlin, pp 153–164

Nelson D (2014) Roadmap to a low carbon electricity system in the US and Europe. Climate Policy Initiative, San Francisco

Smart grid vision and roadmap for India. India Ministry of Power (2013)

Scheer D, Konrad W, Scheel O (2013) Public evaluation of electricity technologies and future low-carbon portfolios in Germany and the USA. Energ Sustain Soc 3:1–13

Kuo TC, Chen HM, Liu J et al (2014) Applying multi-objective planning in low-carbon product design. Int J Precis Eng Manuf 15(2):241–249

Zhang Q, Tezuka T, Mclellan BC et al (2012) Scenario analysis of low-carbon smart electricity systems in Japan in 2030. In: Yao T (ed) Zero-carbon energy Kyoto 2011, Part 1. Springer, Berlin, pp 33–44

Pudjianto D, Aunedi M, Djapic P et al (2014) Whole-systems assessment of the value of energy storage in low-carbon electricity systems. IEEE Trans Smart Grid 5(2):1098–1109

Zeng B, Zhang JH, Yang X et al (2014) Integrated planning for transition to low-carbon distribution system with renewable energy generation and demand response. IEEE Trans Power Syst 29(3):1153–1165

Chen Q, Kang CQ, Xia Q et al (2010) Power generation expansion planning model towards low-carbon economy and its application in China. IEEE Trans Power Syst 25(2):1117–1125

Ji Z, Kang CQ, Chen QX et al (2013) Low-carbon power system dispatch incorporating carbon capture power plants. IEEE Trans Power Syst 28(4):4615–4623

Lu SY, Lou SH, Wu YW et al (2013) Power system economic dispatch under low-carbon economy with carbon capture plants considered. IET Gener Transm Distrib 7(9):991–1001

Turconi R, Tonini D, Nielsen CFB et al (2014) Environmental impacts of future low-carbon electricity systems: detailed life cycle assessment of a Danish case study. Appl Energy 132:66–73

Roelicha K, Dawson DA, Purnell P et al (2014) Assessing the dynamic material criticality of infrastructure transitions: a case of low carbon electricity. Appl Energy 123:378–386

Walmsley MRW, Walmsley TG, Atkins MJ et al (2014) Minimising carbon emissions and energy expended for electricity generation in New Zealand through to 2050. Appl Energy 135:656–665

Zhang Q, Mclellan BC, Utama NA et al (2011) A methodology for designing future zero-carbon electricity systems with smart grid and its application to Kansai area, Japan. In: Design for innovative value towards a sustainable society: Proceedings of the 7th international symposium on environmentally conscious design and inverse manufacturing (EcoDesign’11), Kyoto, Japan, 30 Nov–2 Dec 2011, pp 50–54

Jin C, Wang P, Xiao JF et al (2014) Implementation of hierarchical control in DC microgrids. IEEE Trans Ind Electron 61(8):4032–4042

Cristea C, Lopes JP, Eremia M et al (2007) The control of isolated power systems with wind generation. In: Proceedings of the 2007 IEEE Lausanne power technology conference, Lausanne, 1–5 Jul 2007, pp 567–572

Mohd A, Ortjohann E, Sinsukthavorn W et al (2009) Supervisory control and energy management of an inverter-based modular smart grid. In: Proceedings of the IEEE PES power systems conference and exposition (PSCE’09), Seattle, 15–18 Mar 2009, 6 pp

Omari O, Ortjohann E, Mohd A et al (2007) An online control strategy for DC coupled hybrid power systems. In: Proceedings of the 2007 IEEE power engineering society general meeting, Tampa, 24–28 Jun 2007, 8 pp

Johnson NG, Glassmire JW, Lilienthal PD (2012) Comparing power system architectures for domestic lighting in isolated rural villages with HOMER. In: Proceedings of the 2012 IEEE global humanitarian technology conference (GHTC’12), Seattle, 21–24 Oct 2012, pp 375–380

Anwari M, Rashid MIM, Muhyiddin HTM et al (2012) An evaluation of hybrid wind/diesel energy potential in Pemanggil Island Malaysia. In: Proceedings of the 2012 international conference on power engineering and renewable energy (ICPERE’12), Bali, 3–5 Jul 2012, 5 pp

Yadav DK, Girimaji SP, Bhatti TS (2012) Optimal hybrid power system design using HOMER. In: Proceedings of the IEEE 5th India international conference on power electronics (IICPE’12), Delhi, 6–8 Dec 2012, 6 pp

Kansara BU, Parekh BR (2011) Modeling and simulation of distributed generation system using HOMER. In: Proceedings of the 2011 IEEE international conference on recent advancements in electrical, electronics and control engineering (ICONRAEeCE’11), Sivakasi, 15–17 Dec 2011, pp 328–332

Sureshkumar U, Manoharan PS, Ramalakshmi APS (2012) Economic cost analysis of hybrid renewable energy system using HOMER. In: Proceedings of the 2012 international conference on advances in engineering, science and management (ICAESM’12), Nagapattinam, 30–31 Mar 2012, pp 94–99

De Brabandere K, Vanthournout K, Driesen J, et al (2007) Control of microgrids. In: Proceedings of the 2007 IEEE power engineering society general meeting, Tampa, 24–28 Jun 2007, 7 pp

Alam MS, Gao DW (2007) Modeling and analysis of a wind/PV/fuel cell hybrid power system in HOMER. In: Proceedings of the 2nd IEEE conference on industrial electronics and applications (ICIEA’07), Harbin, 23–25 May 2007, pp 1594–1599

Rohani A, Mazlumi K, Kord H (2010) Modeling of a hybrid power system for economic analysis and environmental impact in HOMER. In: Proceedings of the 18th Iranian conference on electrical engineering (ICEE’10), Isfahan, 11–13 May 2010, pp 819–823

Konig O, Hametner C, Prochart G et al (2014) Battery emulation for power-HIL using local model networks and robust impedance control. IEEE Trans Ind Electron 61(2):943–955

Reddy YJ, Kumar YVP, Raju KP et al (2012) Retrofitted hybrid power system design with renewable energy sources for buildings. IEEE Trans Smart Grid 3(4):2174–2187

Nehrir MH, Wang C, Strunz K et al (2011) A review of hybrid renewable/alternative energy systems for electric power generation: configurations, control, and applications. IEEE Trans Sustain Energ 2(4):392–403

Shaahid SM, El-Amin I (2009) Techno-economic evaluation of off-grid hybrid photovoltaic-diesel-battery power systems for rural electrification in Saudi Arabia—a way forward for sustainable development. Renew Sustain Energy Rev 13(3):625–633

Dihrab SS, Sopian K (2010) Electricity generation of hybrid PV/wind systems in Iraq. Renew Energy 35(6):1303–1307

Microgrid Power System Design Services Using HOMER. http://www.homerenergy.com/microgrid_power_system_design_services.html

Felix A, Simoes MG (2006) Integration of alternative sources of energy. IEEE Press, Hoboken

Hyderabad planet. www.hyderabadplanet.com

Atmospheric science data center (2013) http://eosweb.larc.nasa.gov

The mean monthly wind speed in Hyderabad, India. http://www.weather-and-climate.com/average-monthly-Wind-speed,Hyderabad,India

Southern Power, Distribution Company of T.S.Limited (2014) http://www.apcentralpower.com

Barley CD, Winn CB (1996) Optimal dispatch strategy in remote hybrid power systems. Sol Energy 58(4–6):165–179

Jalivand A, Kord H, Rohini A (2009) Design, control & power management for a hybrid PV/WG/FC system for standalone applications. In: Proceedings of the 14th electrical power distribution conference (EPDC’09), Kerman

Wang CS, Nehrir MH (2008) Power management of a stand-alone wind/photovoltaic/fuel-cell energy system. IEEE Trans Energy Convers 23(3):957–967

Nelson DB, Nehrir MH, Wang C (2006) Unit sizing and cost analysis of stand-alone hybrid wind/PV/fuel cell power generation system. Renew Energy 31(10):1641–1656

Author information

Authors and Affiliations

Corresponding author

Additional information

CrossCheck date: 4 January 2015

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

PAVAN KUMAR, Y.V., BHIMASINGU, R. Renewable energy based microgrid system sizing and energy management for green buildings. J. Mod. Power Syst. Clean Energy 3, 1–13 (2015). https://doi.org/10.1007/s40565-015-0101-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40565-015-0101-7